Can a PET Sheet Extrusion Machine Produce PP, PS, and PLA Materials?

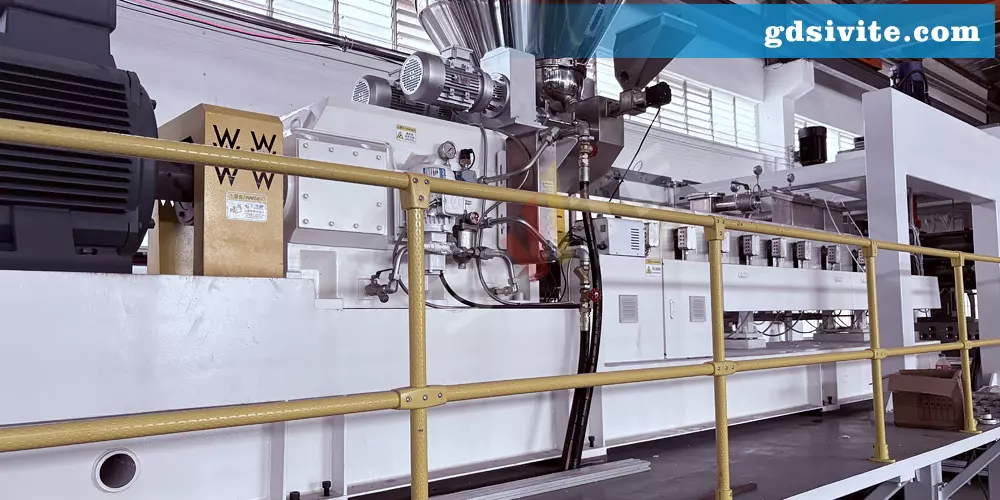

PET sheet extruders are specialized equipment designed to produce polyethylene terephthalate (PET) sheets, which are widely used in packaging, food containers, and other industrial applications. These machines melt and shape PET resin into thin, uniform sheets with high precision. However, many manufacturers wonder if PET sheet extruders can also process other thermoplastics, such as polypropylene (PP), polystyrene (PS), and polylactic acid (PLA). The answer depends on several factors, including machine configuration, temperature control, and screw design.

PET Extruder Compatibility with PP, PS, and PLA: While PET sheet extruders are optimized for PET, some models can be adjusted to process other materials. PP and PS have different melting points and flow characteristics than PET, requiring adjustments to the temperature profile and screw speed. PLA is a biodegradable plastic with a lower melting point and is more sensitive to heat, which means that the extruder must maintain precise thermal control to avoid degradation.If the PET sheet extruder has adjustable parameters and a versatile screw design, it can adapt to these materials, but the efficiency and output quality may vary. Key improvements for multi-material processing: To use a PET extruder to process PP, PS, or PLA, the following improvements may be required: Temperature setting: PP generally requires 200-280°C, PS requires 180-240°C, PLA requires 160-220°C, and PET processing temperature is 250-300°C.

If you want to use a PET sheet extruder to process multiple materials, there are actually many hidden problems, including that each time the material is changed, the material waste of the trial machine is very large, and this kind of one machine with multiple functions will produce better quality products with higher precision than a dedicated model.

Is it feasible to use a PET extruder to process PP, PS, and PLA?

In summary, although a PET sheet extruder can process PP, PS, and PLA after proper adjustment, its efficiency and quality are not as good as a dedicated extruder. Moreover, there is no comparability in quality, especially for some functional materials, it may cause varying degrees of damage to the materials, so it is not recommended to use one machine to share multiple materials.