How Are Thermoforming Machine Sheets Produced?

In the plastics manufacturing industry, thermoformer sheets play a vital role as a base material in the manufacture of a variety of thermoformed products, from food packaging to medical. These plastic sheets are carefully designed to withstand high temperatures and precision forming processes, making them indispensable materials for modern manufacturing. Understanding the production process of thermoformer sheets, the materials used, and their applications can help companies optimize their production processes and ensure the output of high-quality products. At the heart of the process is the thermoformed sheet, which is a key material that determines the quality and functionality of the final product.

1. Understanding Thermoforming Machine Sheets

A thermoforming machine sheet is a flat plastic material heated to a pliable state before being molded into a desired shape. These sheets are typically made from thermoplastic polymers, which soften when heated and harden upon cooling. The production of **thermoforming machine sheets** begins with raw plastic resins, which are processed into uniform sheets through extrusion. Common materials include PET (polyethylene terephthalate), PP (polypropylene), PS (polystyrene), and PVC (polyvinyl chloride), each offering unique properties like durability, flexibility, and heat resistance.

2. The Manufacturing Process of Thermoforming Machine Sheets

The production of **thermoforming machine sheets** involves several key steps:

>> Resin Preparation: Plastic pellets are dried to remove moisture, ensuring optimal melting consistency.

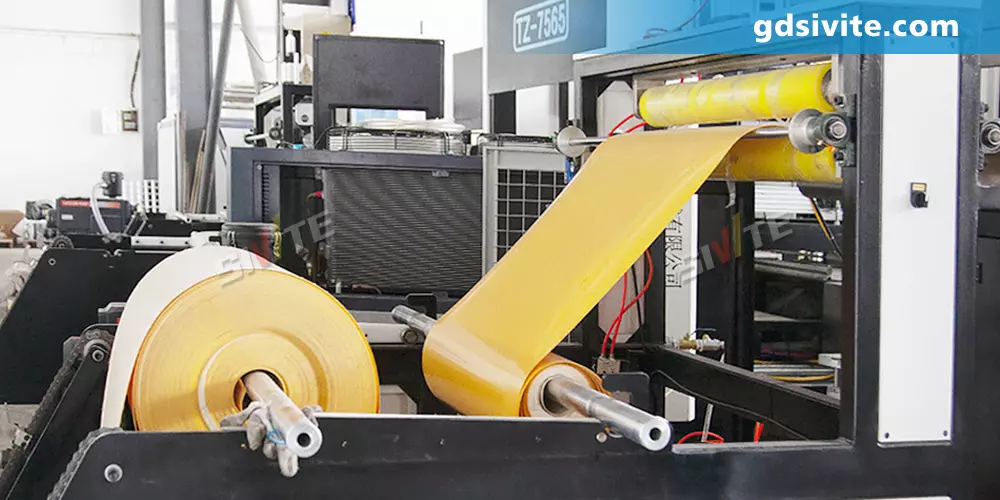

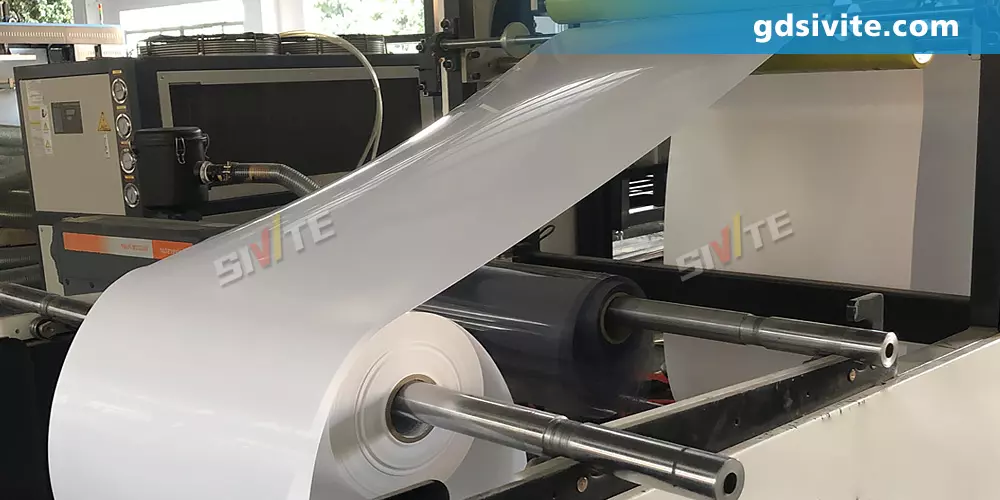

>> Extrusion: The pellets are fed into an extruder, melted, and pushed through a flat die to form a continuous sheet.

>> Cooling & Calendering: The molten sheet is cooled using rollers or water baths, then calibrated to achieve precise thickness.

>> Cutting & Winding: The cooled sheet is trimmed to size and rolled for storage or further processing.

Advanced techniques like co-extrusion allow manufacturers to create multi-layered sheets with enhanced properties, such as improved barrier resistance for food packaging.

3. Key Applications of Thermoforming Machine Sheets

Thermoforming machine sheets are widely used across industries due to their versatility and cost-effectiveness. Common applications include:

- Packaging: Blister packs, clamshell containers, and disposable food trays.

- Automotive: Interior panels, dashboards, and protective linings.

- Medical: Sterile packaging, surgical trays, and disposable medical devices.

- Consumer Goods: Appliance housings, electronic enclosures, and retail displays.

The ability to produce lightweight, durable, and customizable products makes thermoforming machine sheets a preferred choice for manufacturers.

4. Advantages of Using Thermoforming Machine Sheets

Compared to other plastic-forming methods, thermoforming offers several benefits:

- Cost-Efficiency: Lower tooling costs and faster production cycles.

- Material Versatility: Compatible with a wide range of thermoplastics.

- Sustainability: Excess material can often be recycled, reducing waste.

- High Precision: Capable of producing intricate designs with tight tolerances.

These advantages make thermoforming machine sheets ideal for high-volume production while maintaining quality standards.

5. Future Trends in Thermoforming Sheet Production

The thermoforming machine sheet industry continues to evolve with advancements in biodegradable plastics, smart packaging, and automation. Innovations like thinner yet stronger sheets and energy-efficient production methods are shaping the future of thermoforming. As demand for sustainable and high-performance materials grows, manufacturers are investing in eco-friendly resins and advanced extrusion technologies.

When selecting sheet for a thermoforming machine, manufacturers must consider several key factors to ensure compatibility with the thermoforming machine and end-product requirements. The thickness of the sheet directly affects the forming process, with thicker sheets requiring higher forming temperatures and longer cycle times. Thermal stability is another key consideration, as the sheet must be able to withstand the heat of the thermoforming process without warping or degrading. In addition, the shrinkage, optical clarity, and mechanical strength of the sheet must be matched to the specific application. For companies, sourcing sheet from a reputable supplier can ensure consistent quality, reduce production downtime, and minimize material waste. By carefully evaluating these factors, manufacturers can maximize the efficiency and profitability of their thermoforming operations.