It uses thermoforming to process plastic sheets like PP. Depending on the mold shape, it can produce a variety of plastic products, including cups, bowls, plates, and dishes. Compared to thermoforming machines, the key difference lies in the workstations. The plastic cup forming machine utilizes in-mold cutting technology, enabling the forming and cutting process to be completed in a single station. The machine is controlled by a microcomputer programmable controller, offering simple operation and high production efficiency. Combined with an intelligent backend, it can also achieve fully automated, one-stop processing from logo printing to cup sorting and packaging.

2.Food Container Cups: Such as ice cream cups, yogurt cups, pudding cups, etc.

3.Food Packaging Cups: Used for soups, salads, nuts, and other food items.

4.Coffee Cups: Used in coffee shops, tea shops, etc., usually with a lid.

5.Pharmaceutical Containers: Used for packaging certain liquid medicines.

6.Medical Sample Cups: Small containers used for sample collection or laboratory use.

7.Bubble Tea and Juice Cups: Common products for bubble tea shops, juice bars, etc.

Self-developed and mastering core technologies

1 to 1 precise temperature control

Utilizing multi-stage PID intelligent temperature control technology, coupled with a high-precision infrared sensor, this machine achieves ±1°C temperature differential control, ensuring uniform heating of the sheet, preventing localized overheating or cooling, and significantly improving molding accuracy and product consistency.

In-mold cutting technology

The in-mold cutting system enables the production of plastic cups to be completed in a single station, effectively reducing waste and improving production efficiency. It can be freely combined with an intelligent backend to achieve fully automated one-stop completion from pattern printing to cup sorting, counting, and packaging.

Intelligent AI control system

The integrated intelligent AI control system provides 24/7 real-time monitoring of the equipment's operating status. Memory storage and access are quick and easy, allowing even factories without professional operators to easily complete order production. One-click start-up is simple, and remote factory assistance is available for peace of mind.

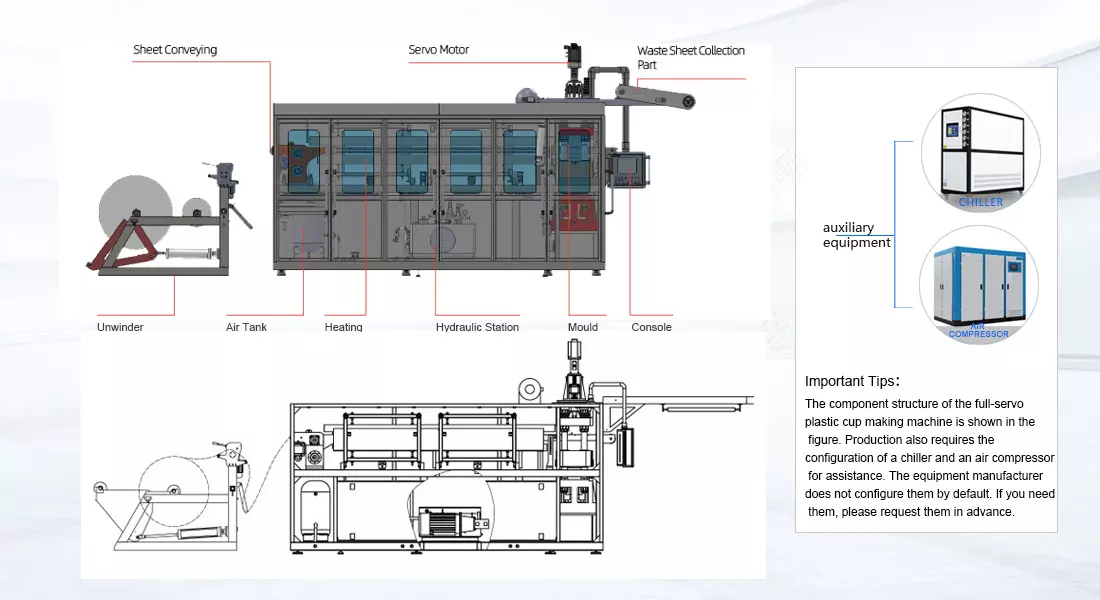

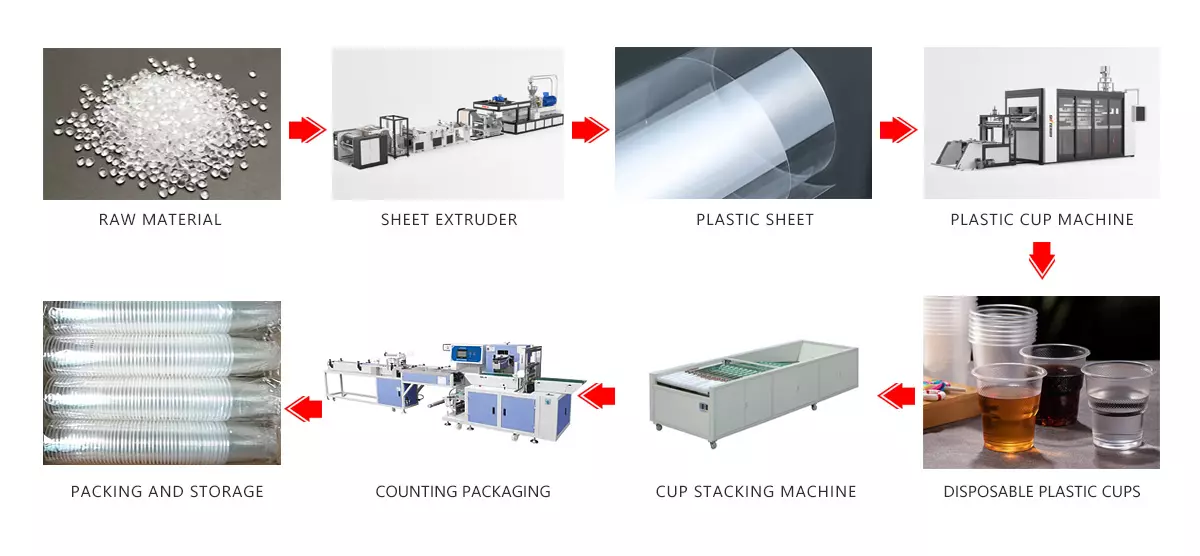

How it works (Complete machine production process)

The complete production line of plastic cup making machines consists of 9 key components, each of which plays a specific role and is seamlessly connected and integrated to achieve precise and efficient production requirements.

1.Unwinder

Stores plastic sheet rolls and facilitates automatic or semi-automatic feeding.Unwinding shaft, tension control system, edge-guiding device (to ensure centered sheet feeding).Single-roll or multi-roll (enables automatic roll switching to minimize downtime).

2.sheet conveying

Transports the sheet from the roll to the heating station with precise speed and positioning.Servo-driven conveyor chains/clamps, gripper mechanisms, photoelectric sensors (for sheet alignment detection).

3.gas tank

The air tank stores compressed air to ensure that the pneumatic system of the plastic cup machine can work stably during the production process, avoiding poor equipment performance or production interruption due to unstable air source.

4.Six-stage heating system

It can soften plastic sheets (such as PET, PP, PS, etc.) and make them ductile, making them easier to shape. The softened plastic can be better shaped in the mold, ensuring the quality and precision of the product. Generally, infrared or ceramic heating bricks are used.

5.Molding (in-mold cutting)

While the molding action is taking place inside the mold, the excess waste at the edge of the formed cup mouth is precisely cut off, realizing the integration of molding and trimming. This not only improves production efficiency, but also reduces waste, saves costs, and improves product quality.

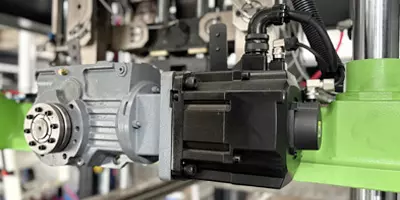

6.servo motor

The entire machine uses a full servo motor power system: providing power for feeding, mold opening and closing, cutting and other actions. Advantages: high positioning accuracy, energy saving, and quiet operation.

7.PLC control system

It adopts the latest AI intelligent control system with integrated data storage function. It can call data at any time for the production of multiple specifications of products, monitor in real time 24 hours a day, and provide feedback on the operating status of the equipment at any time.

8.Waste recycling device

This is the last station of the machine. Its function is very simple, which is to roll up the scraps after forming and cutting for easy recycling and reuse.

The plastic cup making machine has different ways of taking out the products after forming and cutting, depending on the product. Generally, a robot is used to take out the materials. Of course, if the automation requirements are not high, it will also be chosen to blow them out directly and collect them in a box. This needs to be customized according to the product.

1. Sheet Extrusion

First, raw material pellets (such as PET, PP, and PS) are processed through a sheet extruder. Here, the pellets are heated, melted, and extruded into thin sheets by a screw. The thickness and width can be adjusted to meet product requirements. Precise control of temperature and pressure ensures sheet quality and uniformity.

2. Thermoforming

The melted sheet enters a thermoforming machine, typically using positive and negative pressure molding technology. After heating the sheet to the molding temperature using a mold, suction or pressure is applied to form the sheet into the initial shape of the plastic cup. This process ensures precise and consistent cup size and shape.

3. Sorting

The formed plastic cups are then shaped and straightened by automated sorting equipment to ensure each cup has a smooth, defect-free edge. The sorting process can also preheat or cool the cups to ensure optimal physical properties.

4. Counting and Packaging

After forming and sorting, the plastic cups enter the counting and packaging stage. During this process, automated equipment packages the cups according to the set quantity, ensuring the exact number of plastic cups in each bag, and then seals the bags. The packaged cups can then be stored or shipped.

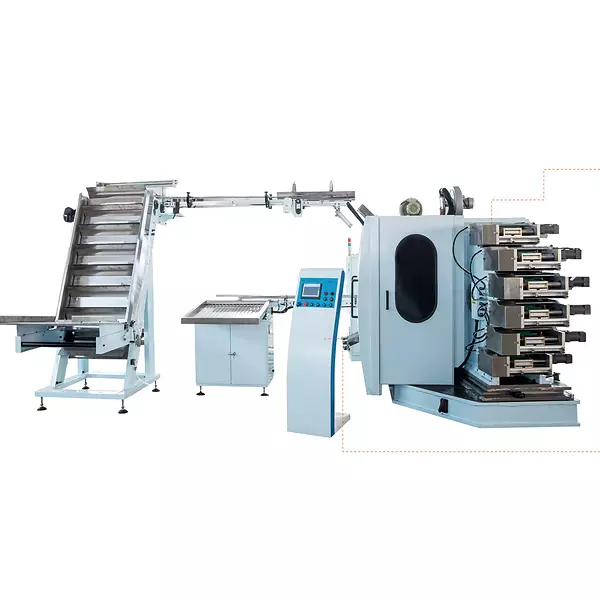

5. Graphic Printing

Many brands use disposable plastic cups that require their own logos to be printed on the cups. Therefore, a six-color printing system is required to fully automate the production of beautifully designed disposable plastic cups.

Each step requires efficient and precise equipment to ensure high-quality, efficient production of plastic cups, while minimizing material waste and optimizing production costs. This entire process typically relies on automated equipment to ensure efficient and precise production.

| Model | SWT-750B | SWT-750D | SWT-850B |

| Mould size | 750*420mm | 750*500mm | 850*550mm |

| Forming Depth(max.) | ≤220mm | ≤220mm | ≤220mm |

| Sheet Thickness | 0.2~3.0mm | 0.2~3.0mm | 0.2~3.0mm |

| Forming Speed(max.) | 28times/min | 28times/min | 28times/min |

| Air pressure | 0.6~0.8Mpa | 0.6~0.8Mpa | 0.6~0.8Mpa |

| Sheet width(max.) | 550~790mm | 550~790mm | 650~890mm |

| Suitable Sheet | PET,PP,PS,HIPS,PVC,PLA..... | ||

| Power supply | AC 380V,50Hz three-phase,four-wire | ||

| Heating Area | 135kw | 135kw | 147kw |

| Rated power | 165kw | 165kw | 182kw |

| Number of workstations | Single station | Single station | Single station |

| Mold Type | Intra-mold cutting | Intra-mold cutting | Intra-mold cutting |

| Weight | 8T | 8.5T | 9T |

| Dimension | L*W*H(4200*2260*2500)mm | L*W*H(4300*2300*2500)mm | L*W*H(5200*2300*2500)mm |

| Main Electrical Components | |||

| Touch Screen | KUNLUN TONGTAI(CHINA) | ||

| PLC Controller | SIEMENS | ||

| Servo Pack | INOVANCE | ||

| Servo Motor | INOVANCE | ||

| Heater | ELSTEIN(Germany) | ||

| Temperature Control Module | TAISONG Temperature control(TAN WAI) | ||

| Solenoid Valve | CKD(Japan) | ||

| Solid State Relay | OMRON | ||

| Circuit Breaker | SCHNEIDER(France) | ||

| AC Contactor | SCHNEIDER(France) | ||

| Power Switch | SCHNEIDER(France) | ||

In what fields can it be applied?

Food industry

We can produce fast food boxes, plastic bowls and plates, biscuit boxes, pastry packaging boxes, fresh food trays, and fruit fresh-keeping boxes such as strawberries, blueberries, and cherries.

Medical industry

It can produce disposable syringe packaging, Tyvek packaging boxes, medical trays, pharmaceutical blister packaging, and medical device housings such as monitors and ventilators.

electronics industry

It can produce electronic pallets, as well as outer packaging and inner pallets for electronic products such as mobile phones, tablets, smart watches, Bluetooth headsets, game controllers, etc.

Cup making industry

We can produce coffee cups, milk tea cups, drinking cups, disposable dishes, milk cups, jelly cups, ice cream cups, disposable beverage cups, etc., as well as their matching cup lids.

automotive industry

Interior parts: instrument panel, door panel, roof, seat shell; exterior parts: bumper, fender, wheel arch, roof luggage box shell; functional parts: battery module shell, motor shell, ventilation duct, etc.

Packaging industry

It can produce cosmetic linings, gift boxes, wine packaging boxes, table and chair panels, cabinet decorative layers, advertising light boxes, as well as various packaging blisters for toothbrushes, toys, etc.

Customers also asked about these related machines