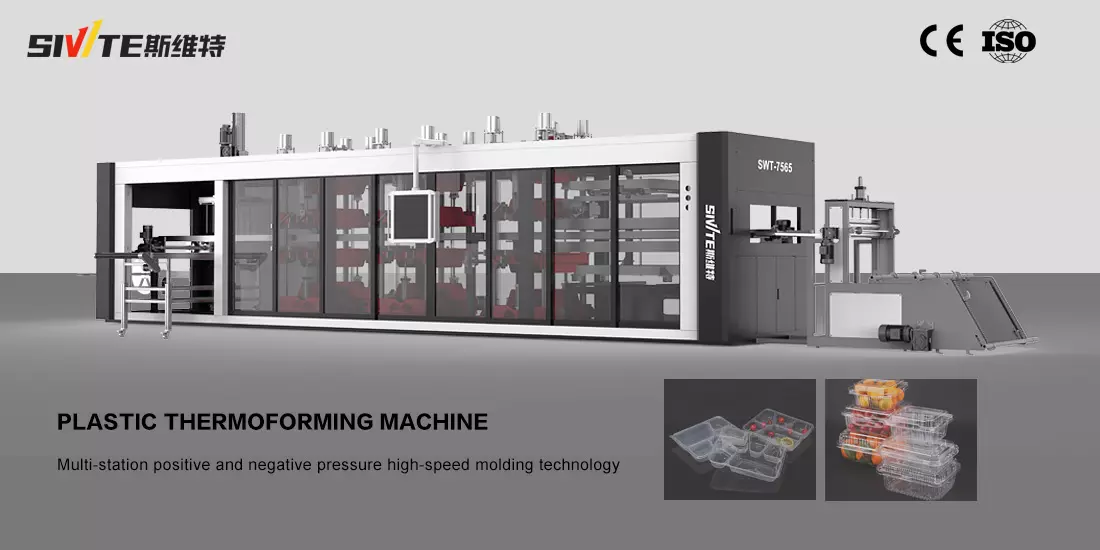

The main workflow of a thermoforming machine includes sheet conveying, heating and softening, forming (positive or negative pressure, or die pressing), cooling, demolding, cutting, and then stacking by a robotic arm. Depending on the product's production process, various models are available, including positive and negative pressure forming multi-station all-in-one machines, negative pressure forming multi-station all-in-one machines, single-station thermoforming machines, and thick sheet thermoforming machines. Its core advantages lie in high production efficiency, low mold costs, and the ability to rapidly produce complex products. It also supports the processing of a variety of materials, including PP, PS, PET, and PVC, making it an essential piece of plastics processing equipment in daily life.

Fruit and vegetable packaging: used for packaging perishable foods such as fruits and vegetables.

Egg trays, fruit trays, etc.: packaging materials used to transport and protect food.

Pharmaceutical packaging: such as pharmaceutical trays and bottle caps.

Medical device packaging: such as syringes and surgical instruments.

Home appliance housings: such as television and refrigerator housings or panels.

In-vehicle accessories: such as instrument panels and door interior panels.

Pencil cases and cosmetics boxes: such as makeup cases and perfume bottle packaging trays.

Electronic product packaging: electronic trays and packaging boxes for electronic products such as headphones.

Self-developed and mastering core technologies

1 to 1 precise temperature control

Utilizing multi-stage PID intelligent temperature control technology, coupled with a high-precision infrared sensor, this machine achieves ±1°C temperature differential control, ensuring uniform heating of the sheet, preventing localized overheating or cooling, and significantly improving molding accuracy and product consistency.

5-Minute Quick Mold Change

Equipped with a patented quick-change mold system, one person can complete mold replacement within 5 minutes. It supports multi-cavity combination mode and flexibly adapts to different product requirements (such as cup lids, trays, and blister packaging), reducing downtime and improving production efficiency by more than 30%.

Intelligent AI control system

The integrated intelligent AI control system provides 24/7 real-time monitoring of the equipment's operating status. Memory storage and access are quick and easy, allowing even factories without professional operators to easily complete order production. One-click start-up is simple, and remote factory assistance is available for peace of mind.

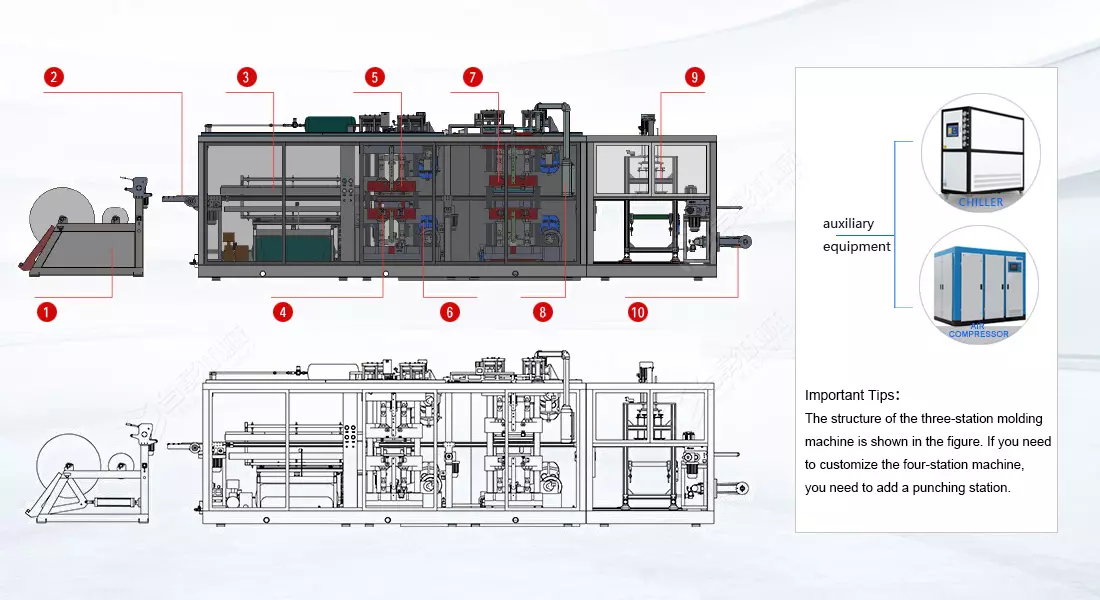

How it works (Complete thermoforming machine production process)

The complete fully automated production of thermoforming machines consists of 10 key components, each of which plays a specific role and is seamlessly integrated to achieve precise and efficient production requirements.

This fully automated thermoforming line combines sheet feedstock with intelligent process control to produce high-quality, single-use plastic packaging for a variety of industrial applications. Synchronous operation of all components ensures consistent product quality while maintaining continuous production.

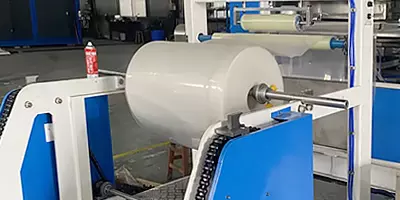

1.Unwinder

Stores plastic sheet rolls and facilitates automatic or semi-automatic feeding.Unwinding shaft, tension control system, edge-guiding device (to ensure centered sheet feeding).Single-roll or multi-roll (enables automatic roll switching to minimize downtime).

2.Sheet Conveying

Transports the sheet from the roll to the heating station with precise speed and positioning.Servo-driven conveyor chains/clamps, gripper mechanisms, photoelectric sensors (for sheet alignment detection).

3.Four-stage heating system

Softens the plastic sheet to a formable temperature (typically 150–300°C) using radiant or convective heat.Provide uniform heating with low energy consumption.Offer fast response and precise temperature control.Multi-section independent heating for different material requirements.

4.T-Shaped Mold Platform

The T-shaped die table design (also called the figure eight die table) has a faster die change speed than the traditional die table, reduces the downtime for die change, has higher production efficiency and is more convenient to use.

5.Forming Station

It uses the most advanced positive and negative pressure thermoforming technology. Its advantage is that no matter how complex the product is, it can be stretched evenly, ensuring the product's uniform thickness and consistent quality.

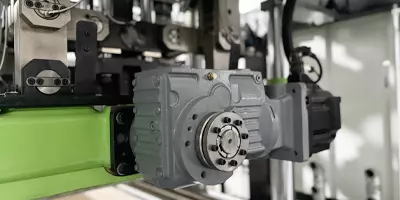

6.Servo Motor

The entire machine uses a full servo motor power system: providing power for feeding, mold movement and cutting operations. Advantages: high-precision positioning, energy saving, and quiet operation.

7.Cutting Station

Separate the molded product from the plastic sheet and remove excess material. Cutting methods: Punch cutting: Mechanical die cutting (suitable for simple shapes). Laser cutting: High precision, no tool wear (suitable for complex contours).

8.PLC Control System

It adopts the latest AI intelligent control system with integrated data storage function. It can call data at any time for the production of multiple specifications of products, monitor in real time 24 hours a day, and provide feedback on the operating status of the equipment at any time.

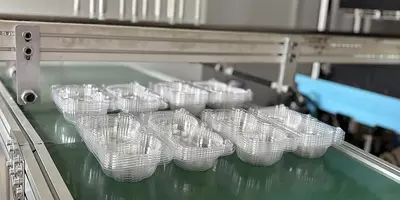

9.Stacking Station

The machine uses a fully automatic robot to produce products that can be taken in or out of the mold. It automatically counts and stacks them neatly for easy packaging. It also supports customization of special stacking stations based on different product characteristics.

10.scrap collection

This is the last workstation of the machine. Its function is very simple, which is to collect the scraps cut off from the cutting station for easy recycling and reuse.

Each solution is optimized based on specific production needs and material properties, providing customers with flexible, efficient, and stable production solutions. Choosing the right thermoforming equipment solution based on actual production conditions and product requirements can significantly improve production efficiency and forming accuracy.

1.Positive and negative pressure thermoforming solutions

* Bidirectional pressure control: Combining positive pressure (compressed air) and negative pressure (vacuum) technology, the molding process is achieved through the synergistic effect of positive pressure and negative pressure adsorption, which is suitable for the molding of high-precision and complex structures.

* The frequency conversion control technology is used, which can save more than 30% of energy. It has better molding effect for complex product structures, and has strong three-dimensional sense of corners and grooves. It is suitable for complex-shaped products such as fresh boxes and electronic trays.2.Negative pressure thermoforming solutions

* Single negative pressure mode: The sheet is softened by vacuum adsorption and then formed into a mold. It has a relatively simple structure and low cost, and is suitable for products with shallow stretch and simple shapes.

* The integrated, punching, cutting, stacking and multi-station fully automated production line adopts negative pressure molding, so there are more choices for molds. Not only aluminum molds, but also copper molds and gypsum molds can be used. It greatly reduces the mold opening cost for small batch and multi-specification orders.3.High-speed servo thermoforming solution

* This is a semi-automatic thermoforming machine model. The difference between it and the all-in-one machine is that it has only one forming station and the forming adopts negative pressure forming technology.

It is the earliest model of thermoforming machine, with both hydraulic and servo configurations. It cannot produce neatly stacked finished products like an all-in-one machine. This machine also needs to be equipped with an independent cutting device for waste edge processing. It is not picky about molds, so some start-ups will still favor it.4.Thick sheet blister thermoforming solution

Different from sheet forming, this is a blister thermoforming machine specifically for sheets with a thickness of 2~12mm. This machine generally needs to be customized according to the product.

Heavy gauge thermoforming refers to shaping thick plastic sheets typically thicker than 3mm, often between 4mm and 12mm. This process is used to make heavy-duty plastic parts that need extra strength and durability, such as automotive panels, appliance housings, and industrial containers. Unlike thin gauge thermoforming, which uses plastic sheets under 3mm, heavy gauge thermoforming is ideal for large, structural plastic components that must withstand wear and stress.

| Positive and negative pressure thermoforming machine | |||

| Model | SWT-7585 | SWT-7565 | SWT-6245 |

| Mould size(max.) | 750*850mm | 750*650(mm) | 620*450(mm) |

| Forming method | Positive And Negative Pressure Forming |

||

| Forming depth(max.) | 140mm | 140mm | 140mm |

| Sheet thickness | 0.16~2.0mm | 0.16~2.0mm | 0.16~2.0mm |

| Forming speed(max.) | 40~50times/min | 40~50times/min | 30~50times/min |

| Air pressure | 0.6~0.8mpa | 0.6~0.8mpa | 0.6~0.8mpa |

| Sheet width(max.) | 410~790mm | 380~760mm | 380~630mm |

| Adaptive material | PET,PP,PS,HIPS,PVC,PLA..... |

||

| Power supply | AC 380V,50Hz,Three-phase,Four-wire (Can be customized according to the power supply voltage requirements of different countries) |

||

| Heatingpower | 117kw | 94.5kw | 91kw |

| Rated power | 153kw | 120kw | 118kw |

| Procedure | Forming-punching hole-cutting-stacking |

||

| Dimension | L*W*H (10.5m*2.15m*2.88m) | L*W*H (9.5m*2.15m*2.8m) | L*W*H (8.0m*2.0m*2.5m) |

| Weight | Around 14T | Around 11T | Around 10T |

| High-speed servo thermoforming machine (SWT-7695) | |||

| Forming method | Negative Pressrue Forming | Adaptive material | PET,PP,PS,HIPS,PVC,PLA.... |

| Mould size(max.) | 760*950mm | Power supply | AC 380V/50Hz(Customizable) |

| Forming depth(max.) | ≤150mm(Customizable) | Heating power | 90Kw |

| Sheet thickness | 0.15~2.0mm | Rated power | 120Kw |

| Forming speed(max.) | 20~40times/min | Procedure | Forming + cutting + stacking |

| Air pressure | 0.6~0.8Mpa | Dimension | L*W*H(10.5m*2.15m*2.8m) |

| Sheet width(max.) | 430~790mm | Weight | Around 11T |

| High-speed servo thermoforming machine (SWT-1220F) | |||

| Forming method | Negative pressure forming | Mould size(max.) | 760*1220mm |

| Forming depth(max.) | 180mm | Sheet thickness | 0.16~20mm |

| Forming speed(max.) | 6~15time/min | Air pressure | 0.6~0.8Mpa |

| Sheet width(max.) | 490~750mm | Adaptive material | PET,PP,PS,HIPS,PVC,PLA..... |

| Power supply | AC 380V,50Hz Three-phase,Four-wire | Heating power | 39KW |

| Rated power | 55KW | Procedure | Forming(Single station) |

| Dimension | 10.5m*2.15m*2.8m(L*W*H) | Weight | 4.8T |

| Main Electrical Components | |||

| Servo pack | Inovance | ||

| Heater | ELSTEIN(Germany) | ||

| Temperature Control Module | TAISONG Temperature control(TAN WAI) | ||

| Solenoid Valve | CKD(Japan) | ||

| Solid State Relay | OMRON | ||

| Circuit Breaker | SCHNEIDER(France) | ||

| AC Contactor | SCHNEIDER(France) | ||

| Power Switch | SCHNEIDER(France) | ||

In what fields can it be applied?

Food industry

We can produce fast food boxes, plastic bowls and plates, biscuit boxes, pastry packaging boxes, fresh food trays, and fruit fresh-keeping boxes such as strawberries, blueberries, and cherries.

Medical industry

It can produce disposable syringe packaging, Tyvek packaging boxes, medical trays, pharmaceutical blister packaging, and medical device housings such as monitors and ventilators.

electronics industry

It can produce electronic pallets, as well as outer packaging and inner pallets for electronic products such as mobile phones, tablets, smart watches, Bluetooth headsets, game controllers, etc.

Cup making industry

We can produce coffee cups, milk tea cups, drinking cups, disposable dishes, milk cups, jelly cups, ice cream cups, disposable beverage cups, etc., as well as their matching cup lids.

automotive industry

Interior parts: instrument panel, door panel, roof, seat shell; exterior parts: bumper, fender, wheel arch, roof luggage box shell; functional parts: battery module shell, motor shell, ventilation duct, etc.

Packaging industry

It can produce cosmetic linings, gift boxes, wine packaging boxes, table and chair panels, cabinet decorative layers, advertising light boxes, as well as various packaging blisters for toothbrushes, toys, etc.

Customers also asked about these related machines