What components make up a complete PET sheet extrusion line?

In the plastic manufacturing industry, PET sheet extrusion lines are essential for producing high-quality polyethylene terephthalate (PET) sheets used in packaging, food containers, and various industrial applications. Understanding the key components of a PET sheet extrusion line is crucial for optimizing production efficiency and ensuring consistent product quality.

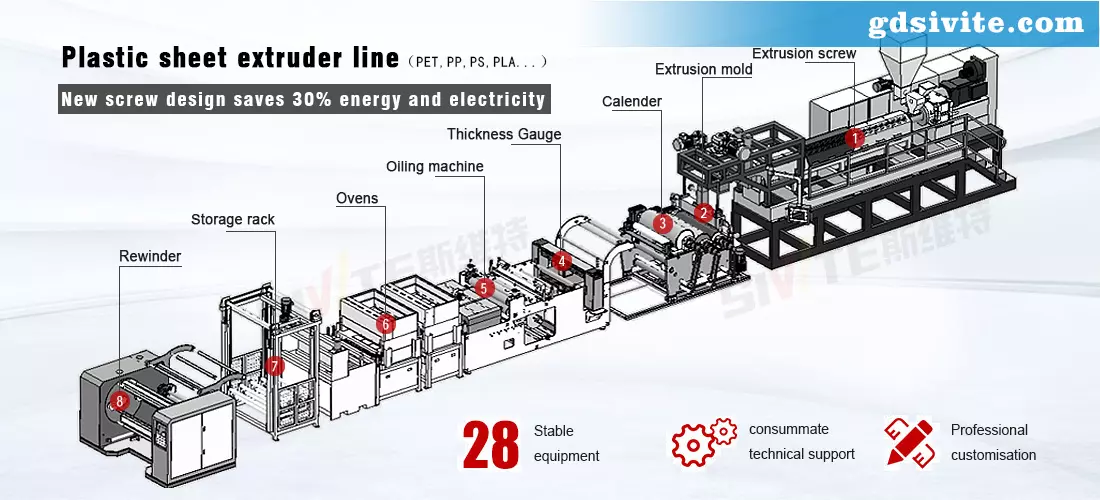

This article will take a deep dive into the 8 main components that make up a PET sheet extrusion line and detail their functions and importance in the extrusion process.

1. Extruder Screw (Extrusion Screw)

The extruder screw is the heart of the PET sheet extrusion line. It is responsible for melting and homogenizing the PET resin pellets before they are shaped into sheets. The screw design—including its length, compression ratio, and flight depth—directly affects the melting efficiency and final sheet quality.

Key features of an efficient extruder screw:

- High compression ratio for uniform melting

- Precision-engineered flights to prevent material degradation

- Corrosion-resistant materials to handle PET’s processing requirements

2. Extrusion Die (Sheet Die)

The extrusion die, also known as the sheet die, shapes the molten PET into a flat sheet. It ensures uniform thickness distribution across the sheet width.

Important aspects of the extrusion die:

- Adjustable lip gap for precise thickness control

- Heating elements to maintain consistent melt temperature

- Uniform flow distribution** to prevent defects like streaks or uneven edges

3. Three-Roll Calender (Calendering Unit)

After exiting the die, the molten PET sheet passes through a three-roll calender (also called a calendering unit or chill roll stack). This component cools and solidifies the sheet while providing a smooth surface finish. Functions of the three-roll calender:

- Precise thickness calibration

- Surface gloss enhancement

- Cooling control to prevent warping

4. Thickness Gauge (Thickness Measurement System)

A thickness gauge (or online thickness measurement system) monitors the sheet’s thickness in real time. This ensures consistency and helps detect deviations early.

Benefits of an advanced thickness gauge:

- Non-contact measurement (laser or beta-ray sensors)

- Automatic feedback control to adjust extrusion parameters

- Data logging for quality assurance

5. Lubrication Unit (Anti-Static Coating Machine)

The lubrication unit (or anti-static coating machine) applies a thin layer of lubricant or anti-static agent to the PET sheet. This prevents sticking and improves handling during further processing.

Key advantages:

- Reduces friction in downstream processes

- Prevents static buildup

- Enhances sheet surface properties

6. Heating Oven (Thermoforming Pre-Heater)

Some PET sheet extrusion lines include a heating oven to preheat the sheets before thermoforming. This ensures optimal forming conditions and reduces material stress.

Functions of the heating oven:

- Uniform heat distribution

- Adjustable temperature zones

- Energy-efficient heating methods (infrared or convection)

7. Sheet Accumulator (Buffer Storage System)

A sheet accumulator (or buffer storage system) temporarily stores the extruded sheet before it moves to the winding stage. This helps maintain continuous production even if downstream processes slow down.

Why it’s important:

- Prevents production stoppages

- Allows for quality inspection

- Improves line efficiency

8. Automatic Winding Machine (Roll-Up System)

The final component in a PET sheet extrusion line is the automatic winding machine, which rolls the finished sheet into large rolls for storage or further processing.

Key features:

- Tension control to avoid wrinkles or stretching

- Automatic sheet collection, cutting and roll changing

- Automatically calculate the length of the meter, correct the deviation, and rewind neatly

A PET sheet extrusion line consists of multiple precision-engineered components, each playing a critical role in ensuring high-quality sheet production. From the extruder screw to the automatic winding machine, every part must function optimally to achieve consistent output. By understanding these eight core components for maximum efficiency and product quality.