Why must the plastic cup making machine mold use in-mold cutting?

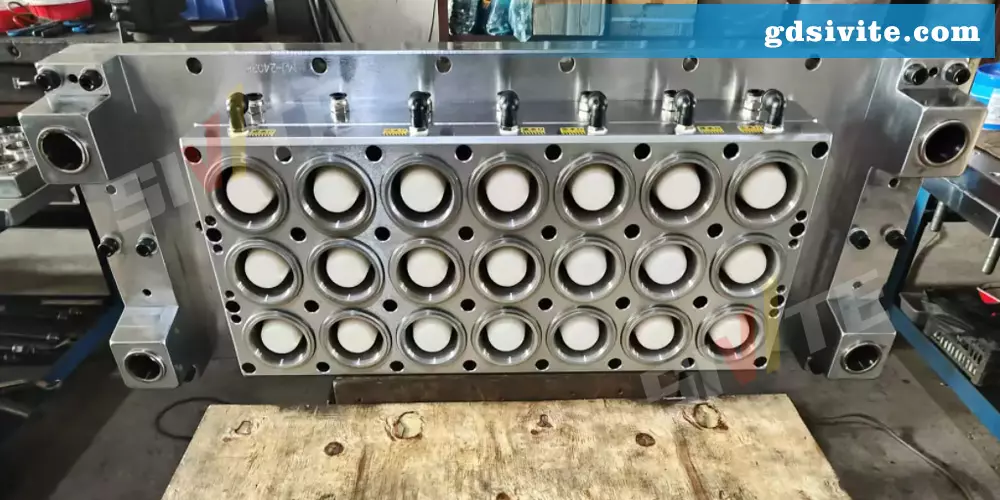

Introduction to Plastic Cup Making Machine Molds

In the manufacturing of plastic cups, the plastic cup making machine mold plays a critical role in determining product quality and efficiency. Among various molding techniques, **in-mold cutting (IMC)** has become an essential process for producing high-precision plastic cups. But why is an **in-mold cutting plastic cup making machine mold** so important? This article explores the key reasons, benefits, and industry trends surrounding this advanced molding technology.

Superior Precision and Consistency

One of the primary reasons for using an in-mold cutting plastic cup making machine mold is its ability to deliver unmatched precision. Traditional post-molding trimming methods often result in uneven edges, requiring secondary processing. In contrast, IMC molds integrate cutting mechanisms directly into the molding process, ensuring clean, uniform edges every time. This precision reduces material waste and enhances the overall aesthetic and functional quality of the plastic cups.

Additionally, consistency is crucial in large-scale production. A plastic cup making machine mold with in-mold cutting ensures that every cup meets exact specifications, minimizing defects and improving production efficiency. Manufacturers relying on high-speed automation particularly benefit from this technology, as it eliminates the need for additional trimming stations.

Cost Efficiency and Reduced Waste

Another significant advantage of using an in-mold cutting plastic cup making machine mold is cost savings. Traditional trimming processes require extra labor, machinery, and energy consumption. By integrating cutting into the mold itself, manufacturers streamline production, reducing operational costs.

Moreover, in-mold cutting minimizes material waste. Since excess plastic is trimmed within the mold, scrap rates are significantly lower compared to external trimming methods. This efficiency not only cuts costs but also supports sustainable manufacturing practices—a growing priority in the plastics industry.

Enhanced Durability and Production Speed

Durability is another critical factor favoring in-mold cutting plastic cup making machine molds. The integrated cutting blades are designed for long-term use, maintaining sharpness over thousands of cycles. This durability translates to fewer mold replacements and lower maintenance costs.

Additionally, production speed is greatly improved. Since trimming happens simultaneously with molding, cycle times are shorter compared to traditional methods. For high-demand manufacturers, this means faster turnaround times and increased output without compromising quality.

Industry Trends and Future Developments

As the demand for high-quality plastic cups grows, the adoption of in-mold cutting plastic cup making machine molds continues to rise. Innovations in mold design, such as self-sharpening blades and advanced cooling systems, are further enhancing efficiency. Automation and smart manufacturing trends also drive the need for integrated solutions like IMC molds, ensuring seamless production workflows.

In conclusion, the **plastic cup making machine mold** with in-mold cutting technology offers unmatched precision, cost savings, durability, and speed—making it an indispensable tool for modern plastic cup manufacturers. As the industry evolves, this advanced molding method will remain a cornerstone of efficient and sustainable production.

750 fully automatic plastic cup making machine and 850 servo plastic cup making machine optimize the plastic cup making machine mold by using in-mold cutting. Its innovative technology and super high efficiency can always keep ahead of competitors and continuously supply high-quality products to the market.